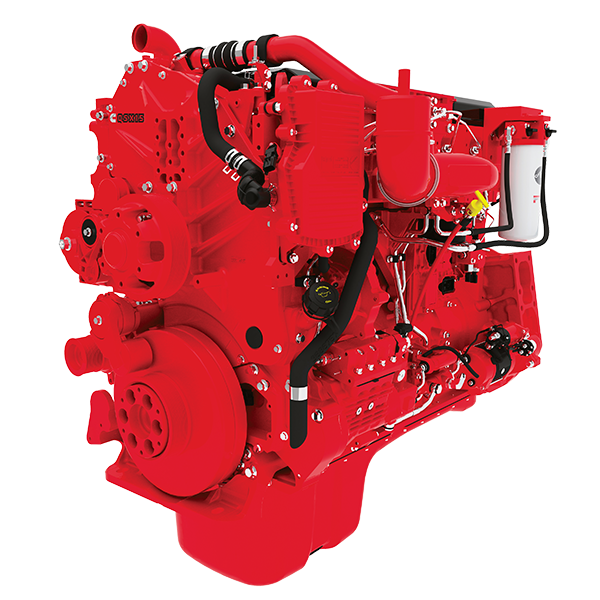

QSX15 (Tier 4 Final/Stage IV)

336 - 503 kW

2237 - 2779 N•m

Applications

Available Regions

Overview:

Better Performance. Where You Need it Most.

Whether you are manufacturing a large excavator, wheel loader, grader, rock drill or compressor, the QSX15 is engineered to deliver the economical, reliable power and performance that you expect from a Cummins engine. In fact, the QSX15 for Tier 4 Final offers ratings that are capable of achieving over a 50 percent increase in torque while at the same time getting better fuel economy.

Every major component and system is designed by Cummins for total quality control, building on a proven engine with fully integrated electronics. Increased control over oxides of nitrogen (NOx) with the addition of Selective Catalytic Reduction (SCR) has enabled modifications to increase combustion efficiency. This results in higher fuel efficiency and better transient response. SCR combined with the Cummins Diesel Particulate Filter (DPF) ensures an additional margin of Particulate Matter (PM) reduction, optimizing performance, which gives the QSX15 one of the highest power densities of any engine in its class. Strong performance and durability, exceptional dependability and superior fuel economy give you every reason to choose the QSX15 for your heavy-duty equipment.