What is an aftertreatment system?

An aftertreatment system is a method or device for reducing harmful exhaust emissions from internal-combustion engines. In other words, it is a device that cleans exhaust gases to ensure the engines meet emission regulations.

|

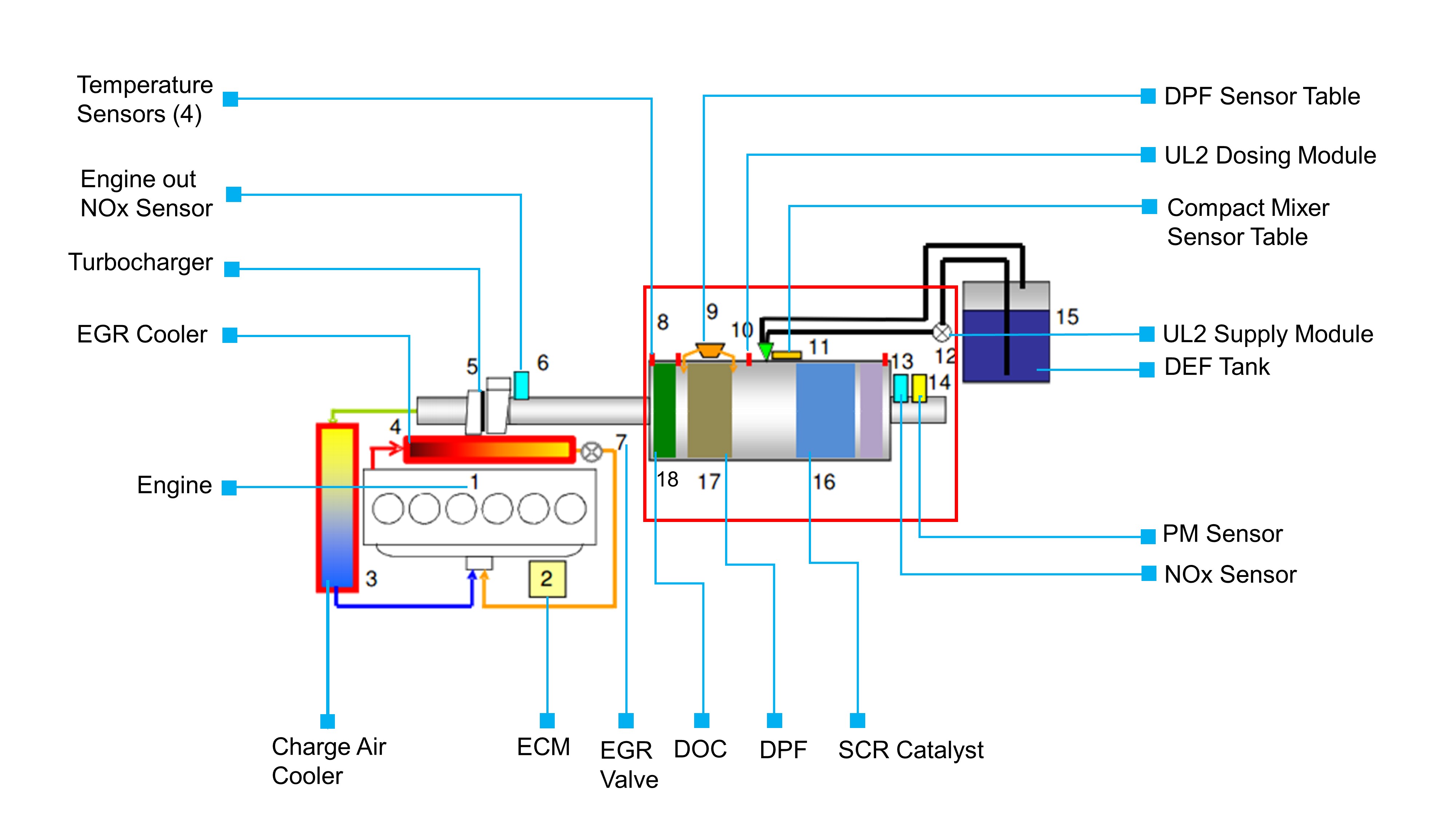

1 - Engine 2 - ECM 3 - Charge Air Cooler 4 - EGR Cooler 5 - Turbocharger 6 - Engine Out NOx Sensor |

7 - EGR Valve 8 - Temperature Sensors (4) 9 - DPF Sensor Table 10 - UL2 Dosing Module 11 - Compact Mixer Sensor Table 12 - UL2 Supply Module |

13 - NOx Sensor 14 - PM Sensor 15 - DEF Tank 16 - SCR Catalyst 17 - DPF 18 - DOC |

How does an aftertreatment system work?

The harmful emission gases in the exhaust stream move from the exhaust side of the turbo to the aftertreatment system (outlined in red).

The Cummins Particulate Filter contains the Diesel Particulate Filter (DPF) which collects and oxidizes carbon to remove particulate matter (PM) by more than 90%; the Diesel Oxidation Catalyst (DOC) aids in this process and is also contained in the Cummins Particulate Filter. The exhaust passes from the turbo through the DOC and enters the DPF.

After collecting the particles from the gases in the DOC and DPF, there is still nitric oxide (NO) and nitrogen dioxide (NO2) left in the exhaust. In order to reduce the NOx levels a light mist of urea (Diesel Exhaust Fluid (DEF) or AdBlue) is injected into the hot exhaust stream in the Decomposition Reactor.

The exhaust progresses from the Decomposition Reactor into the SCR system which converts the toxic NOx and urea mixture into harmless nitrogen gas (N2) and water vapor (H2O), which effectively eliminates harmful emissions resulting in near zero emissions from the exhaust.